Borie Fasteners is a professional Hemlock rivet manufacturer and supplier, we are committed to providing clients with superior fastening solutions. Hemlock rivet customized available in material, length, diameter, surface treatment.

Standard:

Hemlock rivetHead Type:

Dome Head/Countersunk Head/Large FlangeMaterial:

Aluminum/Steel/Stainless Steel/Copper/Brass/MonelCertificate:

ISO9001/IATF16949Finish:

zinc plated/paintedFactory:

We are a factory with 19 years of R&D experienceMOQ:

10000pcsWhat is hemlock Blind Rivets?

Hemlock rivet, also known as hemfirm hemlock rivet or hem hock blind rivet.

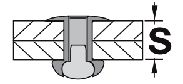

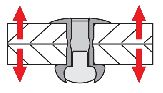

Hemlock rivet refers to a type of fastener used in various industries, including aviation and manufacturing. It is a solid cylindrical pin with a preformed head on one end and a tapered shaft on the other. The head is larger in diameter and acts as a stopper to hold the rivet in place once it is inserted into a hole. Hemlock rivets are commonly made of strong and durable materials like steel or aluminum. They are typically used to join or fasten together two or more materials, such as metal sheets or structural components, by deforming the rivet's shaft and creating a permanent connection. Hemlock rivets are widely utilized for their reliability and strength in ensuring secure and long-lasting structural integrity.

Diameter size:

4.8mm, 6.4mm, 7.8mm

Material (Body/Mandrel)

Aluminum/ Aluminum

Steel/ Steel

Stainless steel/ Stainless steel

Head Style

Dome Head Rivets

Advantage of Hemfirm rivet

| High strength | Excellent durability | Easy installation | Resistant to vibration and shock | Provides a secure and permanent fastening | Suitable for a wide range of materials | Cost-effective solution |

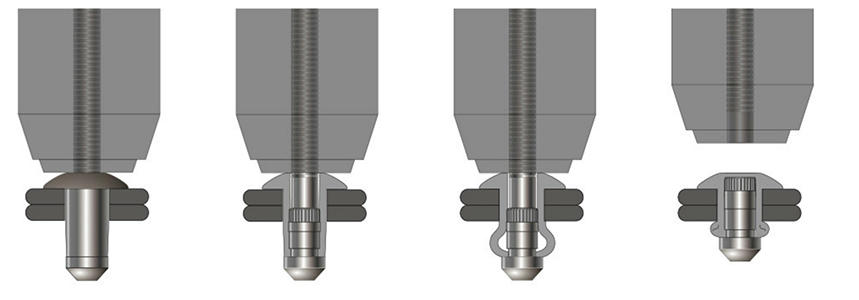

How Does Hemlock rivet Work?

ST/ST Dome Head Hem Lock Blind Rivets

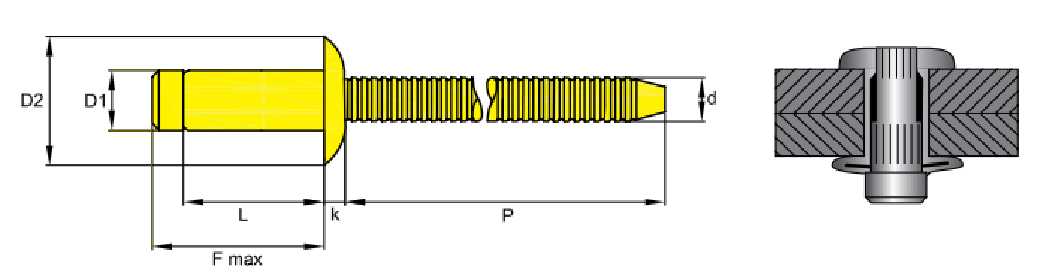

| RIVET DIAMETER /mm |

RIVET LENGTH /mm |

GRIP RANGE /mm |

HEAD DIAMETER /mm |

HEAD HEIGHT /mm |

MANDREL DIAMETER /mm |

MANDREL LENGTH /mm |

HOLE SIZE /mm |

SHEAR /N |

TENSILE /N |

| D1 | L |  |

D2 | k | d | p | DRILL |  |

|

| +1/-0 | MAX. | MAX. | MAX. | MIN. | MIN. | MIN. | |||

| 4.8 +0.08 -0.15 |

9.0 | 1.5-3.5 | 10.2 | 2.5 | 3.10 | 27.00 | 4.9-5.1 | 4500 N | 3500 N |

| 11.5 | 3.5-6.0 | 6000 N | 3500 N | ||||||

| 14.0 | 6.0-8.5 | 6200 N | 3500 N | ||||||

| 16.5 | 8.5-11.0 | 6200 N | 3500 N | ||||||

| 19.0 | 11.0-13.5 | 6200 N | 3500 N | ||||||

| 6.4 +0.08 -0.15 |

9.0 | 1.5-3.5 | 13.4 | 3.5 | 4.20 | 28.00 | 6.6-6.9 | 6800 N | 6400 N |

| 10.5 | 2.8-4.8 | 9200 N | 6400 N | ||||||

| 12.5 | 4.8-6.8 | 10000 N | 6400 N | ||||||

| 14.5 | 6.8-8.8 | 10000 N | 6400 N | ||||||

| 16.5 | 8.8-10.8 | 11000 N | 6400 N | ||||||

| 18.5 | 10.8-12.8 | 11000 N | 6400 N | ||||||

| 20.5 | 12.8-14.8 | 11000 N | 6400 N | ||||||

| 22.5 | 14.5-16.8 | 11000 N | 6400 N | ||||||

| 24.5 | 16.8-18.8 | 11000 N | 6400 N | ||||||

| 26.5 | 18.8-20.8 | 11000 N | 6400 N | ||||||

| 28.5 | 20.8-22.8 | 11000 N | 6400 N | ||||||

| 30.5 | 22.8-24.8 | 11000 N | 6400 N | ||||||

| 32.5 | 24.8-26.8 | 11000 N | 6400 N | ||||||

| 7.8 +0.08 -0.15 |

13.5 | 4.0-7.0 | 18.0 | 4.2 | 5.20 | 28.00 | 8.1-8.3 | 13500 N | 9100 N |

| 16.5 | 7.0-10.0 | 16000 N | 9100 N | ||||||

| 19.5 | 9.0-13.0 | 16000 N | 9100 N | ||||||

| 22.5 | 13.0-16.0 | 16000 N | 9100 N |

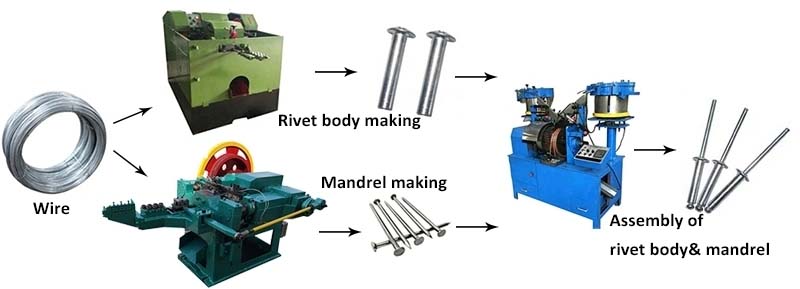

Production Process

Step 1

Blind rivet machine---making the rivet body

Step 2

Nail making machine---making the mandrel

Step 3

Assembly machine--finish the assembly of rivet body and the mandrel

Package

Regular package is small box+ carton+ pallet, or bulk in carton, each carton weights 20-25kgs.

Borie Fasteners can also provide custom packaging service, such as poly bag or plastic bag with client's logo and information.

Application

Blind rivets can be used just about anywhere if they are properly installed. Most of them are used in